Advantages of LSR Injection Molding

Upload Time:

Jan 31, 2026

LSR Injection Molding | Silicone Molding Solutions, Precision LSR Molding Services

一 Durability

LSR is highly resistant to environmental factors such as extreme temperatures, chemicals, and UV radiation, making it ideal for producing long-lasting components in demanding industries.

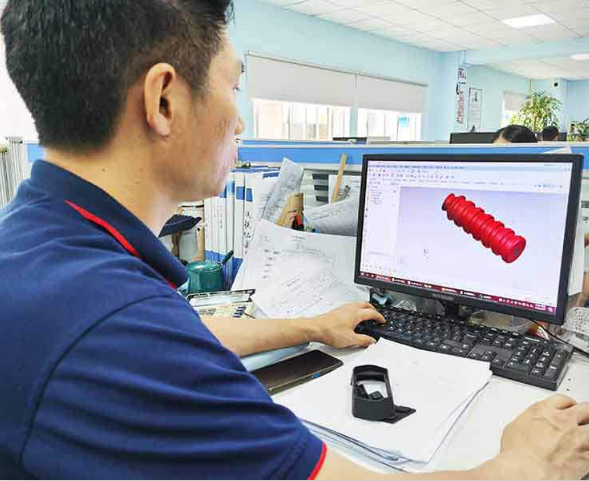

二 Flexibility in Design

LSR can be molded into complex shapes, including thin-walled components, intricate details, and multi-component parts, offering greater design freedom compared to other materials.

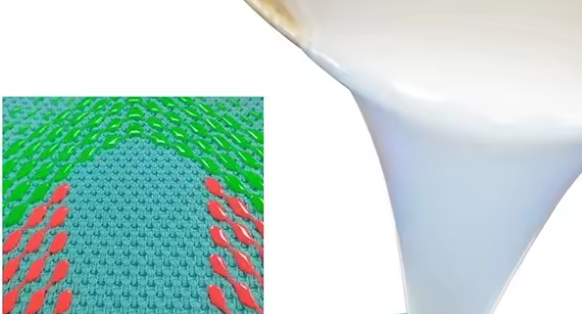

三 Versatility

LSR injection molding can be combined with other materials (such as metals, plastics, ceramics, etc.) through one-piece molding technology to meet special application requirements.

四 Biocompatibility

Because LSR is non-toxic and hypoallergenic, it is widely used in the medical industry for producing components like seals, gaskets, and medical tubing.

五 Fast Production Times

Compared to other manufacturing methods, LSR injection molding offers faster production times, particularly for high-volume runs, due to its efficient and automated process.

六 Cleanliness requirements

ISO-certified Class cleanroom reduces the risk of part contamination from dust and other airborne particles and meets the stringent ISO standards required for hygienic manufacturing.

LSR injection molding offers high precision for micro and thin-wall parts, with excellent biocompatibility and optical clarity. Combined with overmolding, it is widely used in automotive, medical, electronics and optical industries etc.

For more information, please contact us immediately at E-mail: [email protected] or call us +0086 180 33058581

Relevant News