How liquid silicone rubber is used in automotive industries?

Upload Time:

Dec 12, 2025

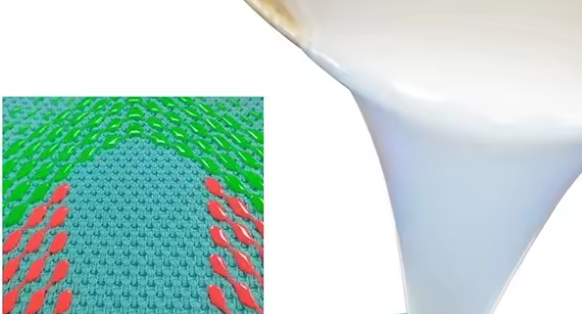

LSR has evolved from a specialty rubber to a critical engineering material enabling the miniaturization, durability, and performance demands of modern electronics and the harsh, high-tech environment of modern and future automobiles, especially electric vehicles.

Liquid Silicone Rubber (LSR) is a high-performance material that has become indispensable in automotive industries due to its unique combination of properties. It's a two-part, platinum-catalyzed elastomer that is injected in liquid form and rapidly vulcanized (cured) under heat.

The automotive drive towards electrification, higher performance, and longer warranties has massively increased LSR demand. It must withstand under-hood temperatures, fuels, and harsh conditions.

1. Sealing and Gasketing (Critical for EVs and ICE alike):

Electric Vehicle (EV) Battery Packs: This is a massive growth area. LSR is used to seal:

Battery Cell Connectors & Busbars: Insulates and protects from moisture and thermal runaway.

Battery Module Housings: Creates flame-retardant (often specific grades are used) and waterproof seals.

Cooling System Seals: For liquid-cooled battery packs.

Headlights and Taillights: High-clarity LSR is used as a hermetic seal between the lens and housing, preventing fogging and condensation. It also acts as a vibration damper.

Engine & Transmission Seals: Gaskets, O-rings, and seals for sensors, oil systems, and covers that must withstand hot oil and high temperatures (often >150°C).

ECU & Sensor Sealing: Protects the "brain" and "nerves" of the vehicle from water, dust, and under-hood chemicals.

2. Ignition Systems & Electrification:

Spark Plug Boots: High-voltage insulation that resists heat, ozone, and tracking.

Charging Connectors (for EVs): Seals for charging inlets and cables that must be durable, waterproof, and safe.

3. Interior & Comfort:

Airbag Covers & Seals: Critical safety components. LSR provides consistent deployment performance over a wide temperature range and long lifespan.

Buttons and Switches: Tactile, durable buttons on the steering wheel, dashboard, and console.

Vibration Damping Mounts: For small components to reduce NVH (Noise, Vibration, Harshness).

4. Advanced Driver-Assistance Systems (ADAS):

Sensor Sealing: Crucially important for LiDAR, radar, and camera housings. LSR provides a stable, waterproof, and optically clear (if needed) seal that does not interfere with signals and protects sensitive optics/electronics.

LSR Manufacturing Advantage:

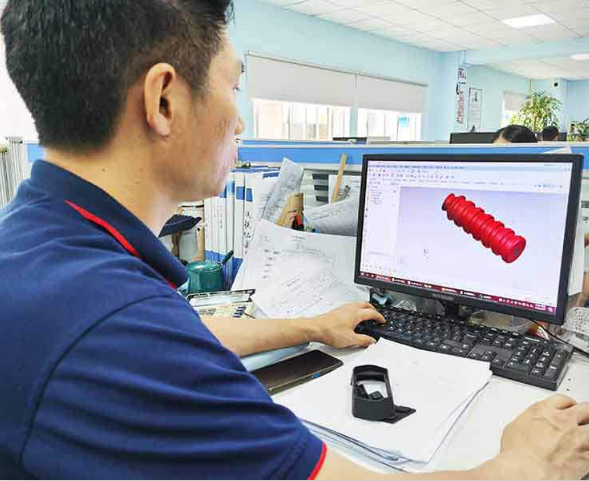

LSR is processed via high-speed, automated Liquid Injection Molding (LIM), which allows for:

Extremely fast cycle times (seconds).

Excellent part consistency and minimal waste.

Insert molding (overmolding onto metal/plastic parts) in one step-perfect for connectors with pins sealed in silicone.

In summary, LSR has evolved from a specialty rubber to a critical engineering material enabling the miniaturization, durability, and performance demands of modern electronics and the harsh, high-tech environment of modern and future automobiles, especially electric vehicles.

Why LSR is Chosen Over Other Materials (Key Properties):

| Property | Benefit for Automotive |

|---|---|

| Wide Temperature Range | Stable from -50°C to +200°C+; doesn't brittle or melt. |

| Excellent Dielectric Strength | Superior electrical insulator, even in thin sections. |

| Fluid & Chemical Resistance | Resists oils, fuels, coolants, and moisture. |

| High Purity & Stability | Platinum-cure system is low-odor, non-bleeding, and suitable for sensitive applications. |

| Transparency & Colorability | Can be optically clear or any color. |

| Biocompatibility (USP Class VI) | Safe for wearables and medical components within devices. |

| Inherent Flame Retardancy | Many grades meet UL94 V-0 without harmful additives. |

| Precision & Complexity |

Low viscosity allows it to fill intricate, micro-molded parts in high-volume LSR injection molding. |

"Beyond high-quality LSR products, we offer comprehensive support to streamline your supply chain and reduce costs:

① Customization Capability: We can adjust LSR formulations (e.g., flame retardant, conductive, food-grade) and provide mold design consultation to match your unique part requirements.

② Stable Supply Chain: As a China-based supplier with 10+ years of silicone experience, we have established long-term partnerships with raw material manufacturers, ensuring consistent supply even during peak demand.

③ Technical Support: Our R&D team (with automotive silicone expertise) provides pre-sales technical consultation, sample testing, and post-sales troubleshooting. We can also assist with product certification (e.g., OEM-specific standards) to accelerate your market launch.

④ Cost-Effective Solutions: We offer competitive pricing with bulk purchase discounts, and our efficient production process (automated mixing and molding) reduces lead times to 7-15 working days for standard orders.

⑤ Quality Assurance: Every batch of LSR undergoes strict quality control (e.g., tensile strength, hardness, chemical resistance testing) with full traceability – we provide test reports for each shipment to ensure compliance.

For more information, please contact us immediately at E-mail: [email protected] or

call us +0086 180 33058581

Relevant News