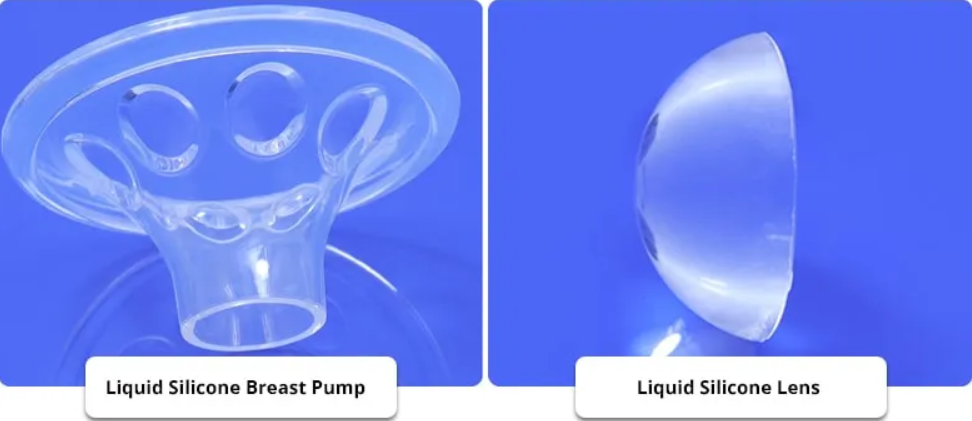

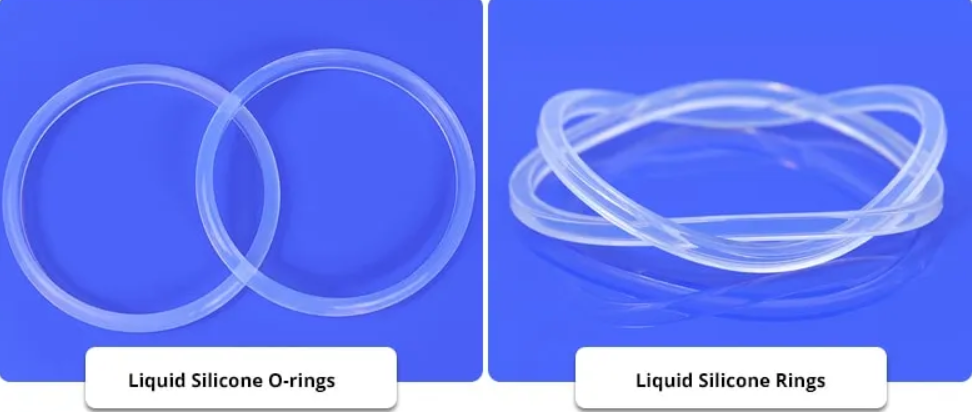

Liquid Silicone Product Production Process

Upload Time:

Aug 12, 2025

The production process for liquid silicone rubber products includes raw material preparation, mixing, degassing, mold preparation, molding, curing, demolding,post-processing, inspection, packaging, storage, and shipping. Each step must be strictly controlled to ensure product quality.

The production process for liquid silicone rubber products primarily includes the following steps:

1. Raw Material Preparation

Silicone Selection: Select the appropriate liquid silicone rubber based on product requirements, typically a two-component system (A and B components).

Additives: Add colorants, catalysts, etc., as needed.

2. Mixing

Proportion Control: Accurately weigh the A and B components according to the formula.

Mixing: Use mixing equipment to blend uniformly, avoiding air bubbles.

3. Mold Preparation

Mold Cleaning: Ensure the mold is free of impurities and residues.

Application of Release Agent: Apply a release agent as needed to facilitate demolding.

4. Molding

Molding Method: Select manual or automatic molding based on the product requirements.

Molding Pressure: Control the molding pressure to ensure the silicone fills

the mold completely.

5. Curing

Temperature control: Set the curing temperature according to the type of silicone.

Time control: Ensure sufficient curing time to allow the silicone to cure completely.

6. Demolding

Demolding operation: Carefully demold after curing to avoid damaging the product.

7. Post-processing

Trimming: Remove excess material.

Cleaning: Clean the product surface to remove release agent residues.

Secondary Curing: Perform secondary curing as needed to enhance performance.

8. Inspection

Visual Inspection: Check the surface for defects.

Dimension Inspection: Ensure dimensions meet specifications.

Performance Testing: Conduct tests such as hardness and tensile strength.

9. Packaging

Packaging Materials: Select appropriate packaging materials.

Packaging Methods: Choose suitable packaging methods based on

product characteristics.

10. Storage

Storage Conditions: Control temperature and humidity in the storage environment.

Storage Duration: Pay attention to the product's shelf life.

11. Shipping

Shipping Inspection: Ensure product quality meets standards.

Logistics Arrangements: Arrange transportation to ensure safe delivery of the product.

Summary

The production process for liquid silicone rubber products includes raw material preparation, mixing, degassing, mold preparation, injection molding, curing, demolding, post-processing, inspection, packaging, storage, and shipping. Each step must be strictly controlled to ensure product quality.

Prime Silinktech (Shenzhen) Co., Ltd. is a specialized manufacturer of liquid silicone rubber products, offering professional production processes for liquid silicone rubber products. Our products are applied across various industries, and we have extensive experience in production.

For more information, please contact us immediately at E-mail: [email protected] or call us +0086 180 33058581

Relevant News