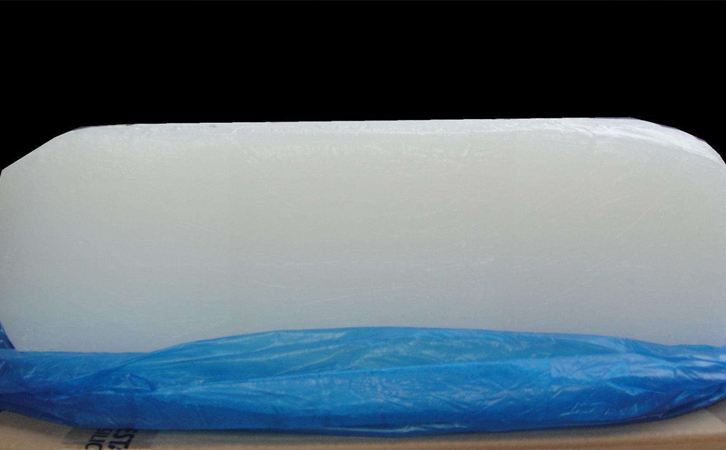

HTV Silicone Rubber Material

The PM7051 series HTV silicone rubber is designed for extrusion molding applications. These silicone rubbers are renowned for their multifunctionality, meeting diverse needs across industries such as aviation, aerospace, electronic, light industry, medical, and daily necessities.

Products

Products DETAILS

HTV Silicone Rubber Material

HTV Silicone Rubber refers to High Temperature Vulcanizing Silicone Rubber. The abbreviation "HTV" stands for "High Temperature Vulcanizing," which indicates that this type of silicone rubber undergoes a vulcanization (curing) process at relatively high temperatures. During this process, the silicone material transforms from a pliable, uncured state into a solid, elastic rubber.

HTV silicone rubber is known for its excellent properties:

1. High Temperature Resistance: It can withstand elevated temperatures without degrading.

2. Low Temperature Flexibility: It remains flexible even at very low temperatures.

3. Electrical Insulation: It provides good electrical insulation properties.

4. Chemical Resistance: It is resistant to many chemicals and environmental factors.

These characteristics make HTV silicone rubber widely used in various industries such as electronics, automotive, aerospace, and medical applications. For example, it is used for manufacturing electronic component insulators, automotive seals, and medical device components.

Product Introduction: PM7051 Series HTV Silicone Rubber

The HTV silicone rubber material of platinum vulcanized silicone rubber is designed for extrusion molding applications. These silicone rubbers are renowned for their multifunctionality, meeting diverse needs across industries such as aviation, aerospace, electrical and electronic, light industry, machinery, construction, chemical, medical, and daily necessities.

Item

Unit

Testing standard

PM7041

PM7051

PM7061

PM7071

(GB/T)

Appearance

Transparent

Cure agent

C-2

Cure Condition

170℃×10 min

Vulcanization dosage

%

2

Shore A Hardness

Shore A

531.1-2008

40±2

50±2

60±2

70±2

Tensile Strength

MPa

528-1998

9

9

9.5

9

Tear Strength

KN/m

529-2008

26

35

45

46

Elongation

%

528-1998

850

700

650

550

Density

g/cm3

528-2008

1.11- 1.15

1.12- 1.16

1.14- 1.19

1.16- 1.20

Compression

%

22 h / 175 °C

25

25

26

28