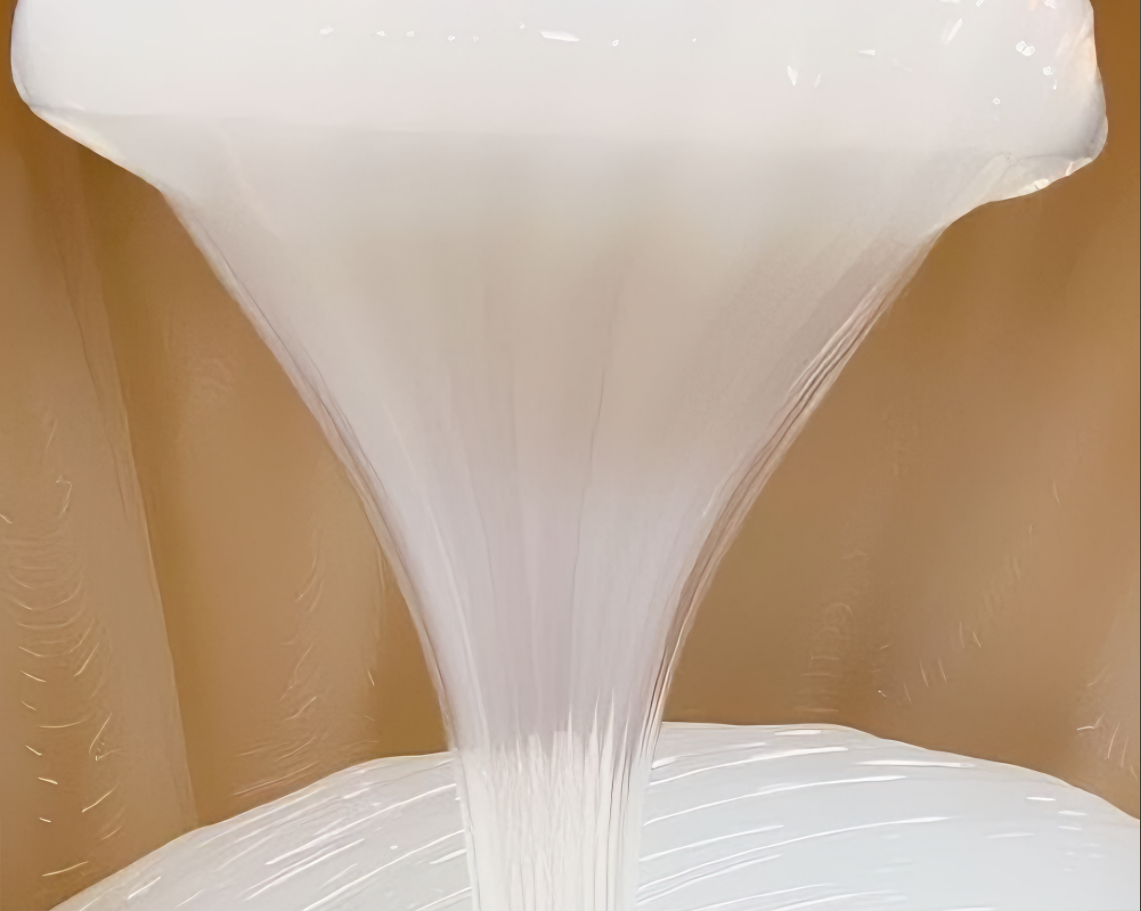

Liquid Silicone Rubber for Medical Use

Medical grade LSR is mainly used in medical supplies such as Foley catheter ,laryngeal mask mask airway ,anesthesia mask,manual resuscitator ,Negative Pressure Drainage Ball etc......

Products

Products DETAILS

Liquid Silicone Rubber for Medical Use

Advantages of Liquid Silicone Rubber For Medical Use

High Biocompatibility

Medical-grade Liquid Silicone Rubber (LSR) is a material that is biologically inert. This means it does not release any harmful chemicals when it comes into contact with organic substances. LSR is inorganic, hypoallergenic, and it does not have any odor or taste. These properties make it suitable for various applications in the medical and food industries. Importantly, medical-grade LSR materials meet the requirements and standards set by ISO-10993, USP Class VI, and RoHS.

Sterilization Options

The ability to sterilize a medical device is vital in reusable medical applications. LSR components offer multiple sterilization options, including Autoclave, E-beam, Ethylene Oxide (ETO), and Gamma radiation processes.

Thermal Stability

LSR exhibits exceptional thermal stability when compared to other injection-molding materials used in medical devices. It maintains its stability across a broad temperature range, from -150°F to 450°F (-101°C to 232°C). Even in extreme temperatures, LSR retains its resiliency, flexibility, and ability to transmit mechanical force effectively. This makes it a reliable choice for medical applications where temperature variations are encountered.

Electrical Insulation

LSR materials demonstrate outstanding electrical insulation properties that remain uncompromised even under harsh environmental conditions. They retain their excellent insulation capabilities despite extreme temperatures, moisture, UV exposure, and ozone. This quality ensures reliable electrical isolation and protection in medical applications. By preventing electrical conductivity issues and minimizing the risk of malfunctions or failures, LSR proves to be an ideal choice for medical silicone rubber products that necessitate effective electrical insulation.

Pleasant Texture

LSR medical-injection molding procedures result in products with surfaces that feel dry and non-tacky to the touch. This characteristic enhances overall comfort. Moreover, LSR can be customized to achieve a variety of textures by modifying the surfaces within the mold cavity. This versatility allows for the creation of medical products with different tactile experiences, catering to specific user preferences and optimizing patient comfort.

Implantable Devices

LSR's exceptional biocompatibility makes it perfectly suited for use in long-term implantable devices like heart valves, cochlear implants, and artificial joints. These devices benefit from LSR's resistance to bodily fluids and tissues, ensuring patient safety and implant longevity.

Closures and Seals

Reliable closures and seals are essential in medical technology to maintain sterility and functionality of medical devices. LSR's chemical resistance and its ability to retain physical properties like a low compression set even under extreme conditions make it an ideal material for manufacturing such components. It is commonly used in seals for dialysis machines, infusion pumps, and other critical medical equipment.

Catheters and Tubes

The flexibility and smooth surface texture of LSR minimize the risk of bacterial adhesion and facilitate the insertion and long-term use of catheters and tubes in medical applications. Its excellent biocompatibility and chemical resistance make it the first choice for these applications, where compatibility with bodily fluids and easy sterilization are crucial.

Wearable Medical Devices

For wearables that enable continuous health monitoring or medication delivery, LSR offers significant benefits through its skin-friendly properties and comfort. From insulin pumps to wearable monitors, LSR ensures that these devices can be worn safely and without skin irritation for extended periods.

Prosthetics and Orthotics

LSR's unique combination of flexibility and strength provides comfort and functionality for users of prosthetics and orthotic devices. Prosthetic liners and supports made from LSR offer a precise fit that adapts to body movements while maintaining durability.

Product description:

Liquid Silicone Rubber (LSR) is a high-purity, two-component, platinum-cured silicone material characterized by low viscosity, good flow, and low shrinkage (less than 0.1%) after curing. It maintains excellent mechanical properties over a wide temperature range (from -60°C to 250°C).

LSR has excellent high and low temperature resistance, chemical resistance, aging resistance, weathering resistance, flame retardancy, as well as good electrical insulation properties and biocompatibility. In addition, LSR is non-toxic, odorless, highly transparent, has a smooth surface, good resilience, tear strength and resistance to yellowing.

Product Features:

1. High transparency, exellent yellowing resistance, anti-aging;

2. Liquid silicone rubber medical accessories with good bio-compatibility;

3. Injection molding;

4. Passing the Bio-compatibility test,Meet FDA,ROHS,LFGB standard.

Technical Data:

Classification

Item No.

Appearance

Hardness

Density

Tensile strength(Mpa)≧

Elongation

Tear strength

Linear Shrinkage(%)

(Shore A)

(g/cm3)

(%)≧

(kN/m)≧

Medical LSR

PM9320EA/B

20±2

1.05~1.11

6

600

20

1.8~2.2

PM9330EA/B

31±2

1.05~1.11

7

600

25

1.8~2.2

PM9340EA/B

40±2

1.10~1.12

8

550

25

1.8~2.2

PM9350EA/B

Transparent

50±2

1.12~1.14

9

450

30

1.8~2.2

PM9360EA/B

60±2

1.13~1.15

9

350

35

1.8~2.2

PM9370EA/B

70±2

1.13~1.15

9

300

35

1.8~2.2